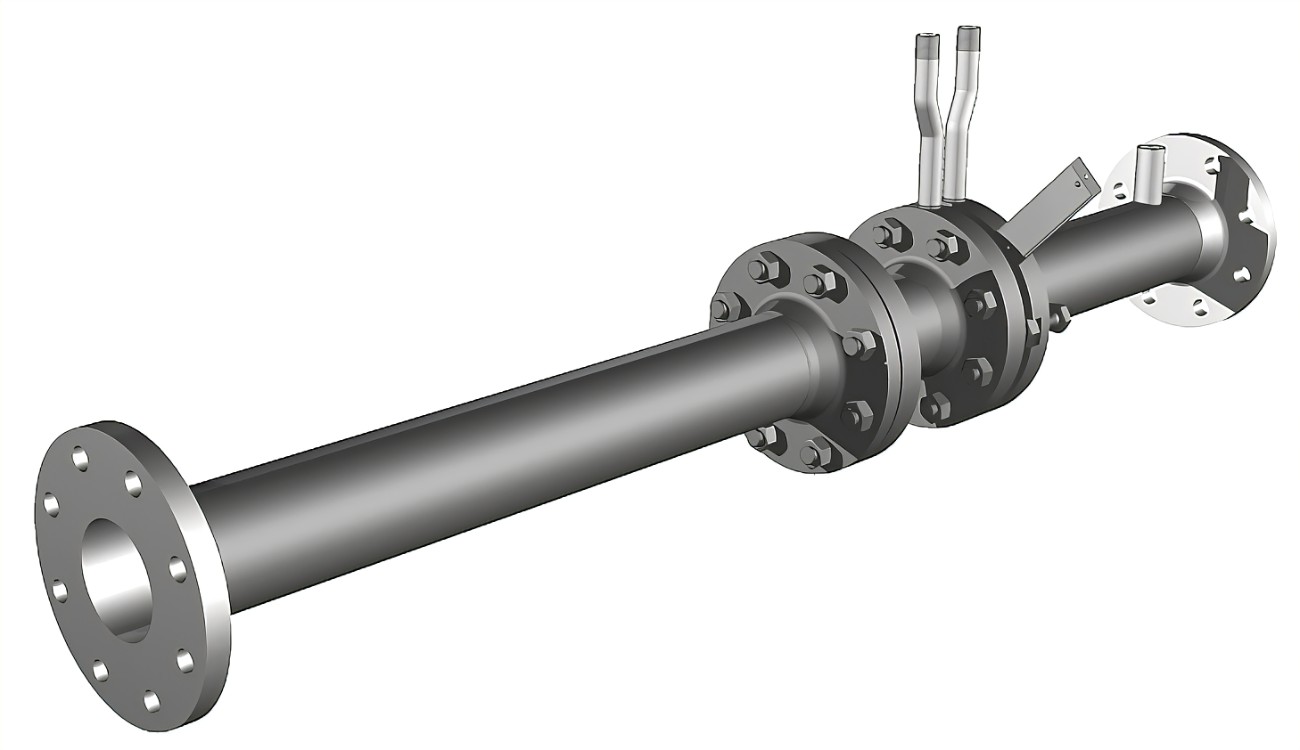

An orifice meter is a device that measures the pressure and flow rate of the fluid or gas passing through it. It mainly consists of three parts an orifice plate, a tube, and plate housing. Out of the mentioned, the orifice plate has the most critical job.

Orifice plates determine the overall performance of the orifice meter. Moreover, they are available in various kinds and differ in their measuring mechanisms. Let’s take a quick view of the types and how they measure the flow rates. You can visit this website: https://www.whmcn.com/ for more technical information about orifice parts.

Working Of an Orifice Plate

Before jumping into the types and their details, let’s quickly look at the working of an orifice plate.

An orifice plate works by measuring the pressure drop across the plate as a liquid flows over the plate. Fluid flows through a restriction and creates a pressure difference between the upstream and downstream points. According to Bernoulli’s equation, the flow rate is proportional to the pressure difference. And an orifice plate works under this equation.

Suppose it’s hard to understand the above explanation. You can understand it as a circular plate resting in a pipe with a hole. The fluid passes through this hole, creating a pressure difference across the plate.

Kinds of Orifice Plates

Now you have a basic idea about the working of the plate. Understanding different kinds will be relatively more straightforward.

Concentric Plates

The most common type of orifice plate is the concentric plate. These plates have a precise and straight hole machined in the middle of the plate. The concentric orifice plates gained their design after tons of research and experimentations.

Therefore, they are highly reliable and preferable in various industrial applications. Everyday use of concentric orifice is with flange taps.

Eccentric Bore Plates

Eccentric bore orifices have a contrasting construction to the concentric ones. These orifices have an off-center hole allowing an uneven portion of liquid to pass over the plate.

Eccentric plates are suitable for use cases where the liquid contains an additional matter. In other words, they work with liquids carrying gases or gases having liquid particles. These plates require more skill from the user as they pose a higher chance of error than concentric plates.

Segmental Bore Plates

The following kind is the segmental plates. These orifices have a semi-circular bore in the center of the plate. Segmental plates are fit for working with liquids with higher concentrations of solids. Solid particles accumulate on concentric and eccentric orifices. But the segmental plates reduce the deposition and allow more accurate measurements.

Quadrant Orifice Plates

Quadrant plates have the most different construction—the upstream functions as the flow nozzle, whereas the downstream function as a sharp edge. Unlike the abovementioned ones, the quadrant plates use both the upstream and downstream systemically to measure the flow rate.

These plates are specific for viscous materials, such as syrups, crudes, and liquids, with Reynold numbers lower than 10,000.

Pros and Cons of Orifice Plates

Now you have a good idea about what an orifice plate is, it’s working, and its types. But why should one use an orifice plate in the first place? Below listed are the highs and lows of the device.

Orifice plates are easier to replace as they aren’t expensive. Moreover, their prices remain similar for various sizes. Measuring fluids is more manageable, and they also guarantee accurateness. They are available in different materials, so you can easily find a fitting piece for your orifice meter. On the downside, orifice plates require a constant high pressure to function correctly. And they are not ideal for liquids with higher viscosity levels.

The Bottom Line

Orifice plates don’t function independently. Instead, they are present within an orifice meter to measure the flow of the passing liquid. Since industrial fluids vary in nature and thickness, different plates are available for various liquids. Hence, it would be best to choose a suitable plate according to your need.

There are four kinds of orifices whose details are above. Orifices are great for accurately measuring flow rates without altering the material’s pressure. But unfortunately, they don’t function well for thicker materials.